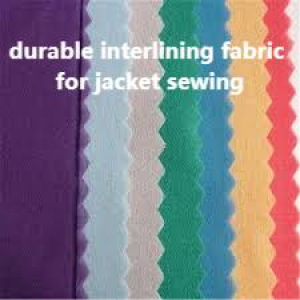

In modern apparel production, Interlining plays a crucial role in enhancing both structure and aesthetic appeal. By strategically incorporating Interlining within garments, designers achieve improved durability, shape retention, and comfort. These supportive layers allow fabrics to maintain their form, ensuring that clothing looks polished and professional while remaining flexible and wearable. The integration of such materials bridges the gap between functionality and design, giving garments a refined finish and longevity that consumers increasingly expect in contemporary fashion.

Advancing Garment Structure

Supportive layers are essential for creating garments that retain their intended shape. Traditional clothing often relied on rigid materials, which could compromise comfort. Today’s innovations favor flexible reinforcements that provide strength without adding bulk. This evolution enables designers to produce apparel that moves naturally with the wearer while maintaining structural integrity, enhancing overall functionality.

Ensuring Durability and Comfort

Quality reinforcements prolong the life of garments by strengthening high-stress areas such as collars, cuffs, and waistbands. These layers minimize deformation from repeated use and washing, helping garments retain their original shape. Comfort is not sacrificed; modern materials are lightweight and breathable, ensuring that wearers experience both resilience and ease throughout daily activities.

Material Innovations

Advances in textile engineering have introduced versatile, sustainable, and high-performance materials. Designers can now access eco-friendly, lightweight reinforcements that seamlessly integrate into a variety of garments. These materials provide excellent support while being gentle on fabrics, reducing stiffness and maintaining drape. Such innovations demonstrate how material science contributes to functional, stylish apparel that meets environmental and consumer expectations.

Broad Applications Across Fashion

Reinforcement techniques are applied across a wide range of clothing types. Jackets and suits benefit from structured layers that maintain crisp lines and professional silhouettes. Shirts, blouses, and dresses gain support in areas such as plackets, collars, and hems, ensuring an elegant finish. Even delicate fabrics can be enhanced subtly without compromising drape, softness, or overall comfort. These applications illustrate the adaptability and necessity of supportive layers in modern fashion.

Expert Implementation for Optimal Results

Proper guidance from experts in garment engineering ensures the successful application of support layers. Knowledge of material selection, placement, and quality control helps maintain aesthetic standards and enhances performance. Manufacturers who leverage expert advice can consistently produce garments that meet high consumer expectations while retaining design intent and functionality.

In conclusion, integrating supportive layers transforms garment performance, aesthetic appeal, and longevity. Designers can deliver apparel that combines style, durability, and comfort, reflecting innovation in modern fashion practices. For more information, visit https://www.interlining-factory.com/news/what-is-interlining-types-applications-and-more.html